Formation techniques

FORMATION TECHNIQUES

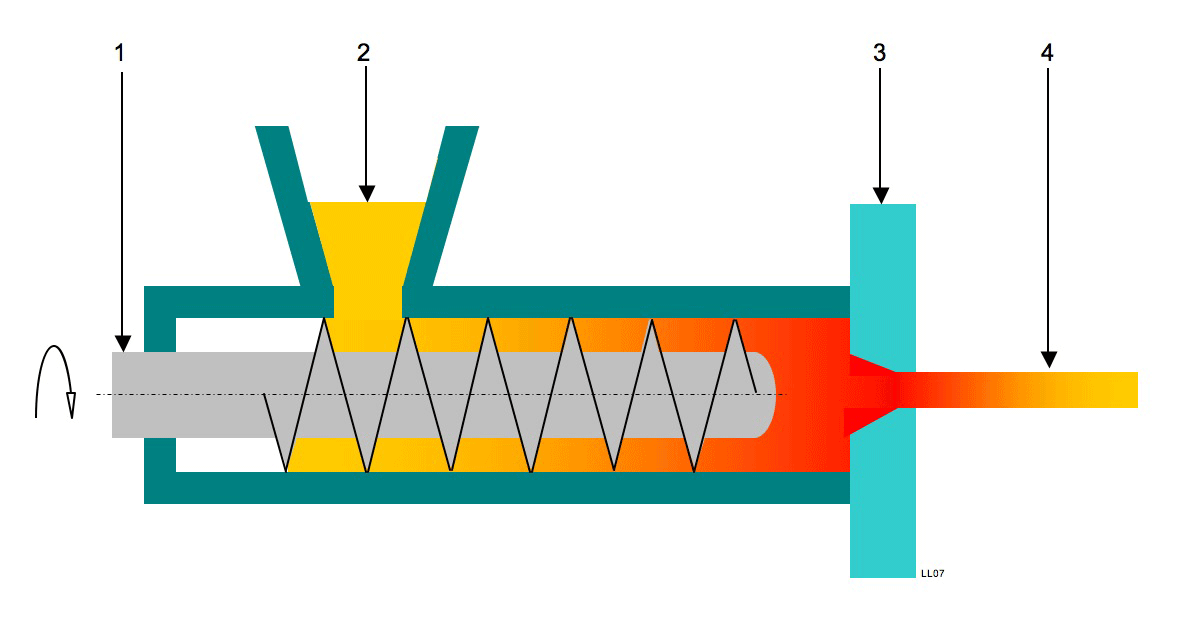

Extrusion

Extrusion is a manufacturing process mainly used to make tubes.

We put thermoplastic material, in granular form, into a heated cylinder.

The granules are melted into a liquid, which is forced through a nozzle by applying pressure. Depending on the nozzle shape we obtain different sections. Then, the material is cooled down in a cold water bath and it solidifies.

Lamination

Materials produced by the lamination method are passed through several hot cylinders to produce sheets of varying thickness.

Vacuum forming

We put thermoplastic material sheets upon a mould. The plastic is heated and the air inside the mould is extracted, the plastic is then pulled against the inside walls of the mould. Once the material has cooled down and is now solidified, we extract it from the mould. Depending on the shape of the mould we obtain different objects.

Injection

We put thermoplastic material, in granular form, into a heated cylinder. The granules are then melted into a liquid, pressure is applied, and the liquid is forced to fill in a mould. When the material has cooled down and is now solidified, we extract it from the mould.

Depending on the mould shape different objects are obtained.

By No machine-readable author provided. LaurensvanLieshout assumed (based on copyright claims). [Public domain], via Wikimedia Commons

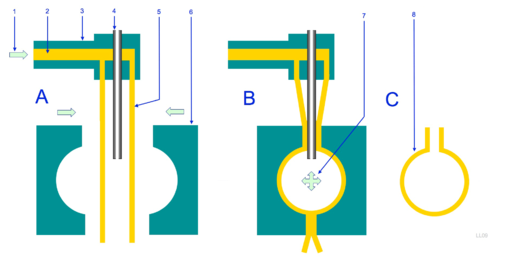

Blow moulding

Blow moulding is a manufacturing process mainly used to make bottles.

We put thermoplastic material, in granular form, into a heated cylinder. We obtain tubes by extrusion and we insert these tubes in a mould. Then, applying heat and air pressure, the plastic is pulled against the inside walls of the mould. When the material has cooled down and is now solidified, we extract it from the mould.

By LaurensvanLieshout (Own work) [GFDL or CC BY-SA 3.0], via Wikimedia Commons

Compression

We put thermoset plastic into a mould made of two coupled parts. One part of the mould is filled with melted plastic while the other one compresses the material inside. Once heat is applied, the plastic adapts to the shape of the mould. Once the plastic has cooled down and is now solidified, it is extracted.

By ariel cornejo (Own work) [CC BY-SA 4.0], via Wikimedia Commons

Last modified: Tuesday, 6 June 2017, 12:51 AM